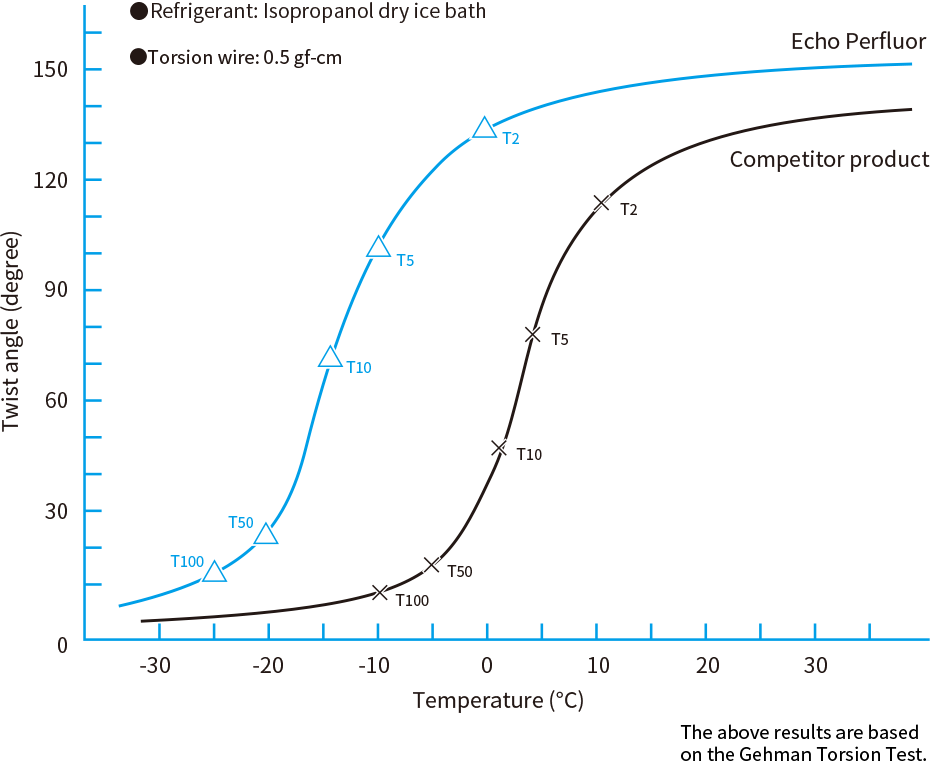

Echo Perfluor

Echo Perfluor is AIR WATER MACH’s proprietary ultra-high performance fluororubber. It maintains the properties of conventional fluororubbers and can be used under severe conditions impossible with conventional rubber including organic polar solvents, various chemicals (*), acids, and alkalis. This revolutionary special synthetic rubber can be used in ways like fluororesin (Teflon).