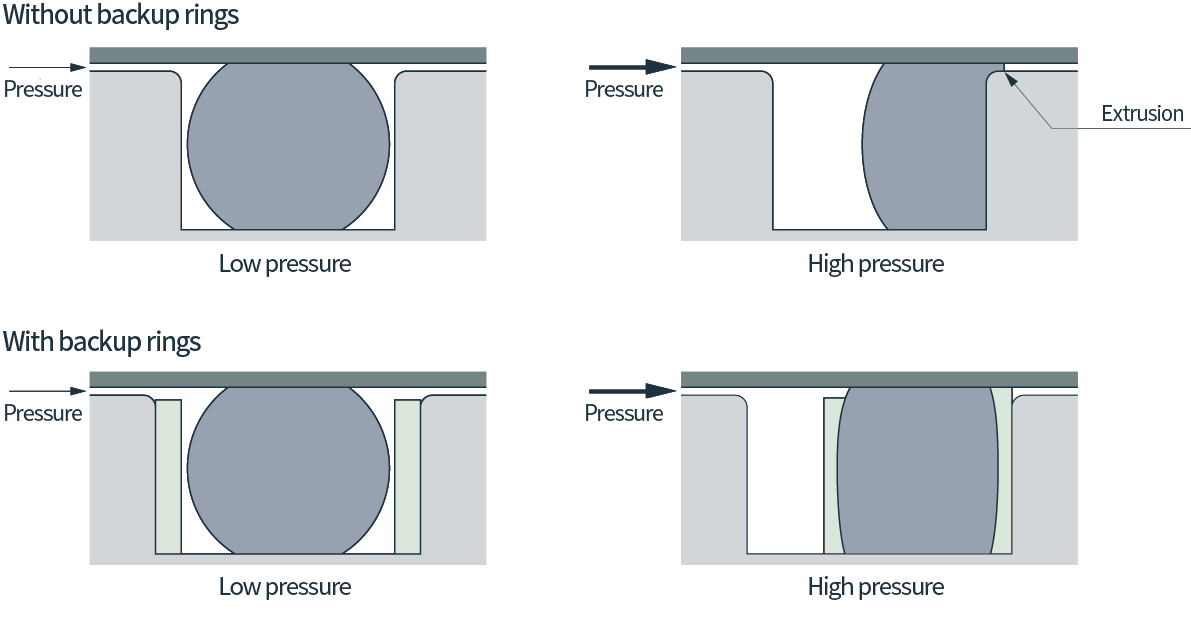

When the pressure of the liquid sealed by an O-ring is too high or the clearance is too large, the O-ring may extrude from the gap and break. Backup rings prevent such extrusion. Even at low pressures where extrusion is not a problem, backup rings prevent accidents due to scratching or spiraling, the main cause of O-ring breakage, and extends the life of the O-ring.

Sealing Business

Fluororesin Product

PTFE (polytetrafluoroethylene) is a type of super-engineered plastic, a fluororesins also known as Teflon. It has excellent heat resistance and the lowest coefficient of friction among plastics. Products with various characteristics can be made by filling PTFE with different kinds of fillers.

Backup Ring

Shape of the Backup Ring

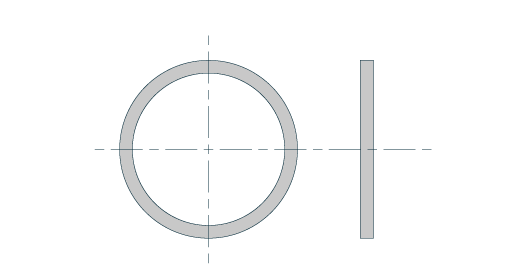

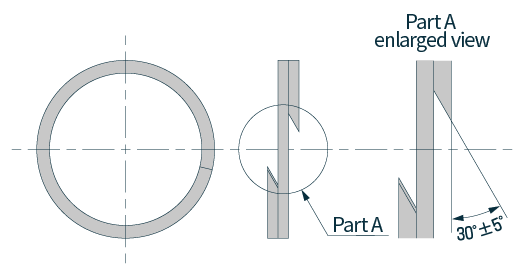

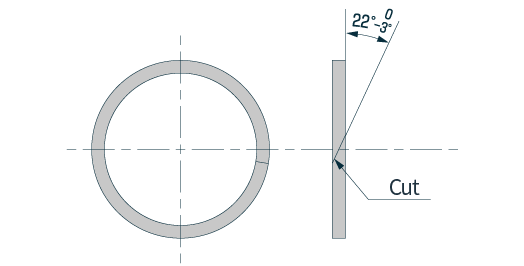

There are three types of backup ring shapes: endless, spiral, and bias cut. Endless backup rings have the greatest effectiveness in use followed by spiral, then bias cut, but bias cut and spiral types are easier to install.

Endless

Spiral

Bias cut

Using Backup Rings

- If pressure is applied from both sides, install the backup ring on both sides of the O-ring. If pressure is applied only from one direction, install a backup ring on the opposite side of the pressure. If extra space is available, we recommend installing two backup rings even when pressure is applied only from one direction.

- Various synthetic resins are used as materials, but PTFE (polytetrafluoroethylene) is generally used in most cases.

- Spiral backup rings should be installed so that the spiral wraps around the deeper side of the groove when installing.

- It can be used in most operating fluids, including general mineral oil-based hydraulic fluids, water-based hydraulic fluids, and synthetic hydraulic fluids.