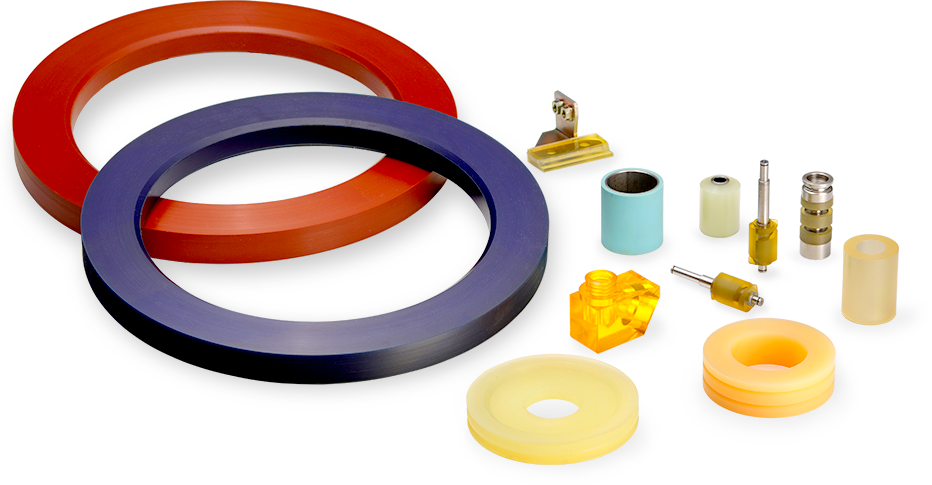

About Our Molded Products

We manufacture and sell high performance, high quality urethane resin products optimized for durability and abrasion resistance in urethane casting. We also handle high performance urethane resin with excellent heat and abrasion resistance.

We take advantage of technology we have cultivated in various fields such as rollers, pulleys, semiconductor related parts, and belts to help you as a business partner in the development and commercialization of casting and molding products.