Production and Quality Control

Unwavering superior quality

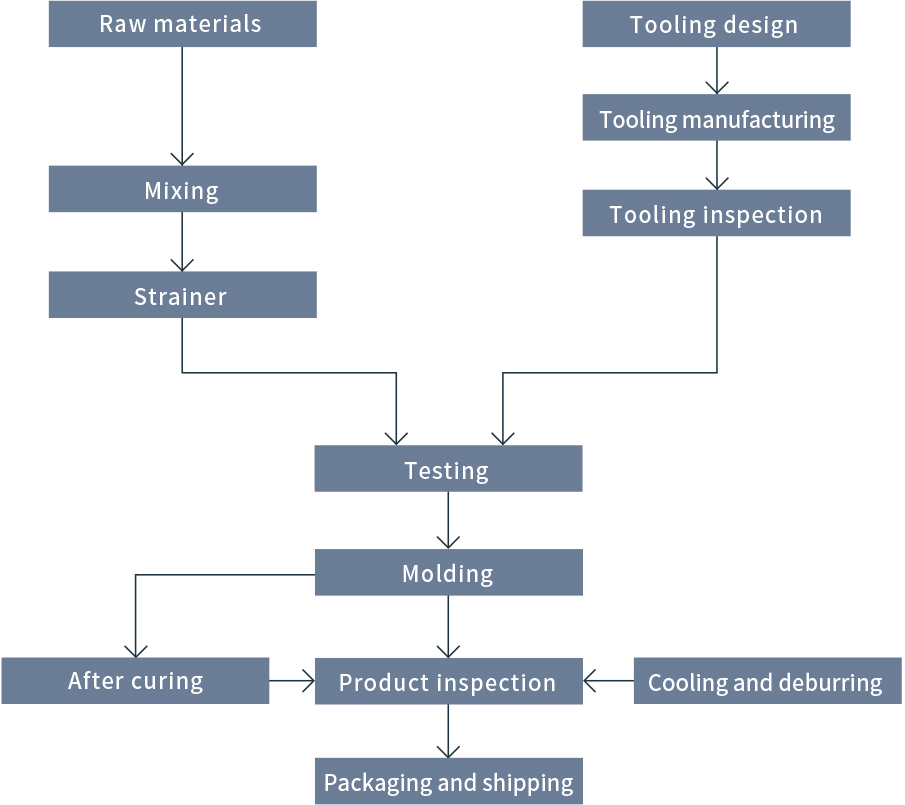

In order to ensure continued delivery of high quality products, we have acquired ISO 9001 certification for our domestic and overseas factories and apply these quality control strategies in all processes. In addition to providing process traceability, we have developed a feedback system for all processes to gather information from customer inquiries, product analysis, and process analysis. We have furthermore developed a production system that integrates all processes from product development and design, to mold production, material, molding, inspection, and packaging. Within this system, we have created an automated line for molding and inspection processes that provides customers with consistent quality products.

High Quality Products

through a Consistent Production and Management System

From the customer perspective, it is the responsibility of the production site to consistently supply high quality products. AIR WATER MACH produces superior products that customers love through an integrated production system that incorporates product design, tooling-making, molding, and packaging all within the company.

Mixing

Experienced engineers perform mixing in collaboration with the system.

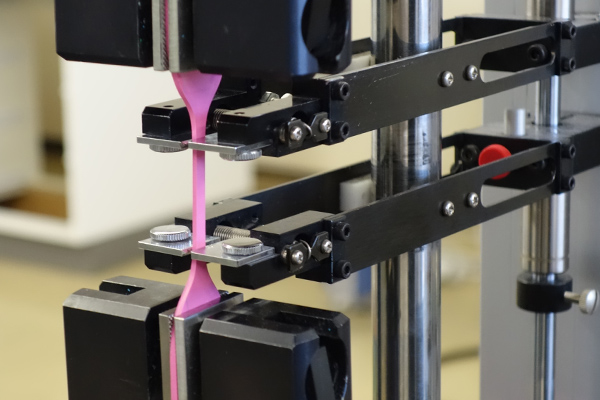

Molding

We also use advanced automatic molding machines for production.

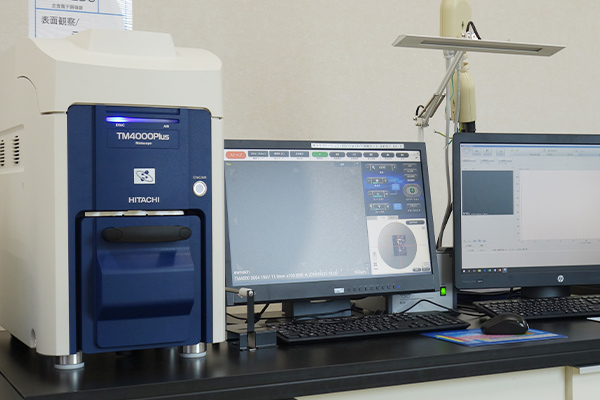

Product inspection

Highly accurate inspections are performed using automatic inspection equipment.

High Performance Products

Produced in a Cleanroom

Our second factory with cleanroom specifications was completed in May 2008. Here, we mainly manufacture high performance products for semiconductors and LCDs. This factory provides extra quality and an excellent environment specialized for high performance products and integrates the entire production process from material mixing to packaging into a cleanroom. New equipment was also introduced to increase the production capacity of perfluoroelastomer products and support the production of high performance, clean specification products.

Air shower

Mixing

Molding

Cleaning

Product inspection

Packaging